Self-propelled Compost Turner-small scale compost turner

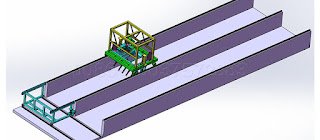

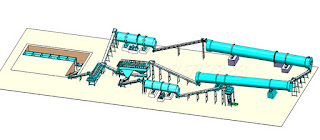

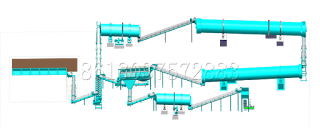

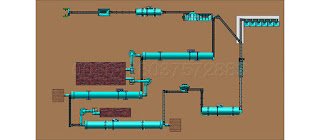

Presentation Self-propelled manure turning machine is one of the center hardware in Organic compost creation plant.With four-wheel propelled,the machine utilizes one-man control and hostile to slip tires.Moving over the strip compost,the gear turn the material and structure another line.The self-impelled fertilizer turning machine is reasonable for different working condition,not just in open ground,also in workshop and greenhouse.The specialized advancement is to incorporate the devastating capacity for the last time of fermentation.The accessional sharp edge can break the square shaping in aging cycle efficient.You can item the manure without an extra crusher,which can low the expense and free the produce capacity. Working cycle The small scale compost machine is one aging manure turning hardware consolidated by two parts:turning gadget and moving device.The moving gadget utilize four wheels,diesel power,anti-slip tires,one-man and guiding wheel operation.The turning gadget'