What aspects should be pai attention to when using organic fertilizer granulator?

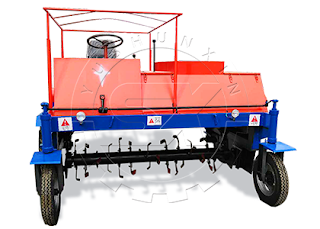

When we buy the new type organic fertilizer pellet equipment , we can not use it with peace of mind after assembling the equipment. We must cultivate professional and experienced operators, and also need professional maintenance personnel. In this way, if the organic fertilizer equipment fails Only timely maintenance will be carried out under certain circumstances, and there will be solutions immediately when equipment problems occur. Similarly, safety issues must also be paid attention to during equipment production! Under safe conditions, people work better. The following editor will introduce to you what you need to pay attention to when using organic fertilizer equipment. Master the performance of the equipment: be familiar with the relevant operation methods, maintenance points, production capacity, and scope of use of the organic fertilizer equipment, and be familiar with the functions of all the controllers and alarm devices of the equipment. Be sure to read the warning instruct