What type of machines can be needed amid the managing of the horse manure ?

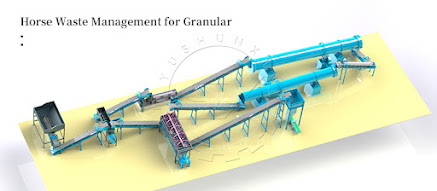

1. Raw material stacking fermentation equipment --Using the trough type stacking machine and plate chain type stacking machine to ferment the horse manre. Realize the new design of compost turner for horse dung, effectively save space and equipment investment funds.

2. The new dry and wet material crusher - the vertical crusher and horizontal crusher is your best chocie for managing the composted horse litter. No screen, even if the material out of the water will be crushed will not be blocked.

3. Automatic multi warehouse batching machine -- according to the customer's horse material varieties designed for 2 warehouse, 3 warehouse, 4 warehouse, 5 warehouse, etc. In the system structure, small and medium-sized distributed control system is adopted to realize decentralized control and centralized management. The system adopts static weighing batching, dynamic equalizing material, so that the good material can achieve a good mixing process before entering the agitator, absorbing the respective advantages of dynamic and static batching. With manual, automatic switching function, online, each control unit according to the communication protocol to exchange information, the upper computer away from the operation site, improve the stability of the system, improve the operator's working environment.

4. Mixing mixer - including vertical mixer, horizontal mixer, double shaft strong mixer, drum mixer, etc. The internal stirring structure is divided into agitator type, spiral type, etc. Design suitable mixing structure according to the characteristics of the horse manure materials. The outlet is designed for cylinder control and baffle control.

5. Organic fertilizer special granulator -- including pan type of pelletzier, new wet granulator, round throwing machine, drum granulator, coating machine, etc. According to the characteristics of raw materials, choose the appropriate granulator.

6. Rotary dryer - alias tumble dryer, biological organic fertilizer dryer, because the temperature of organic fertilizer drying can not exceed 80°, so our dryer adopts hot air drying mode.

7. Cooling machine - and dryer similar appearance, but the material and performance is different. The main machine of the dryer is made of boiler steel, and the main machine of the cooler is made of carbon steel plate.

8. Sieve machine - including drum and vibration type. Screening machine is divided into three screen, two screen and so on.

9. Particle coating machine -- the appearance of the host machine is similar to that of the dryer and cooler, and the internal structure is very different. Stainless steel plate or polypropylene lining is used inside the coating machine. The whole machine includes matching powder mixing machine and oil pump.

10. Automatic measuring and packing machine -- including spiral and straight flow, single head and double head, material is stainless steel and carbon steel, according to the actual needs of customers customized.

11. Conveying equipment, including belt conveyor, screw conveyor, bucket elevator, etc.

The following link will help you to know more information.

https://www.fertilizerfactorymachine.com/horse-waste-management/

Comments

Post a Comment