What is the working principle of new type organic fertilizer granulator?

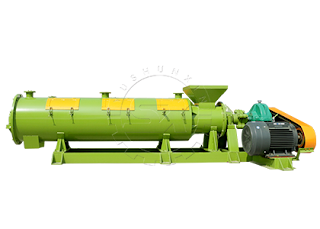

The new type fertilizer granulator is one of the special equipment for organic fertilizer granulation. Because the internal structure is composed of many neatly arranged agitating teeth like a spiral, it is also called an internal rotating agitating tooth granulator. This machine is also suitable for Many raw materials with high water content are granulated, so it is also called wet granulator, which is widely used in the granulation of organic fertilizer raw materials. Due to the high granulation rate, stable operation, sturdy and durable equipment, and long service life, it is selected by the majority of users as the supporting product of the organic fertilizer production line.

The stirring teeth type of pelletizer developed and produced by our unit has a variety of specifications, and we can also develop and produce other specifications of the stirring tooth granulator according to user requirements. The shell of the organic fertilizer granulator is made of thick seamless steel pipe, which is strong and durable, and the stable base design makes it run more smoothly.

The working principle of the new organic fertilizer granulator: The granulator uses the high-speed rotating mechanical stirring force and the resulting aerodynamic force to continuously realize the mixing, granulation, spheroidization, and densification of fine powder materials in the machine. So as to achieve the purpose of granulation.

The particle shape is spherical, the sphericity is ≥0.7, the particle size is generally between 0.3-3 mm, and the granulation rate is ≥90%. The size of the particle diameter can be appropriately adjusted by the mixing amount of the material and the spindle speed. Generally, the lower the mixing amount, the rotation speed The higher the particle size, the smaller the particle size, and vice versa.

Scope of application of the new stirring teeth granulator This granulator is especially suitable for the granulation of light and fine powder materials. The finer the basic particles of the fine powder material, the higher the sphericity of the particles, and the better the quality of the pellets. Typical application materials: chicken manure, pig manure, cow manure, charcoal ash, clay, kaolin, etc. It is specially used for granulation of urban domestic waste organic fermented fertilizers such as organic fertilizer raw materials, livestock and poultry manure, compost fertilizer, green manure, sea manure, cake fertilizer, grass charcoal, soil and miscellaneous fertilizer, three wastes, microorganisms, etc.

The qualified granulation rate of the new type organic granules making equipment is as high as 80-90%, and it is suitable for a variety of different formulas. The compressive strength of the organic fertilizer granulated by this equipment is higher than that of the disc granulator and the drum granulator. The ball rate is less than 15%, and the uniformity of particle size can be adjusted through the stepless speed regulation function of this machine according to user requirements. This machine is more suitable for the direct granulation of organic fertilizer after fermentation, which saves the drying process and greatly reduces the manufacturing cost.

When you require to know more information about the new type organic fertilizer granulator, you can visit the following link.

https://www.fertilizerfactorymachine.com/new-type-organic-fertilizer-granules-making-machine/

Comments

Post a Comment