How to Select the Proper Conveyor Machine for Your Fertilizer Production Plants?

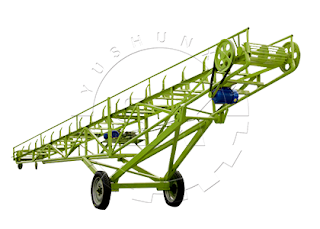

The mobile conveyor belt can be used in the ambient temperature range of 20℃-40℃, and the temperature of the conveyed material is below 50C. The captain and assembly type can be determined according to user requirements. The transmission can be an electric roller or a drive frame. The belt conveyor can carry out the transportation of broken materials and the transportation of finished items. In addition to pure material transportation, it can also be matched with the requirements of the technological process in the cattle production process of various industrial enterprises to form a rhythmic assembly line.

The mobile transportation with advanced conveyor system can transport various materials economically and efficiently. In industrial production, belt conveyors can be used as a link between production machinery and equipment to form continuous production to achieve the continuity and mobilization of production links, increase productivity, and reduce labor intensity. The belt conveyor moves according to the principle of friction transmission. It has the advantages of large conveying capacity, long conveying distance, stable conveying, no relative movement of materials and conveyor belt, low noise, simple structure, convenient maintenance, low energy consumption, standardized components. The mobile conveyor is mainly composed of two end rollers and a closed conveyor belt tightly sleeved on them. The roller that drives the conveyor belt to rotate is called the drive roller. The other roller that only changes the direction of the conveyor belt is called the reversing roller. The driving roller is driven by a motor through a reducer, and the conveyor belt is dragged by the friction between the driving roller and the conveyor belt. Drive rollers are generally installed at the discharge end to increase traction and facilitate dragging. The material is fed from the feeding end, falls on the rotating conveyor belt, and is driven by the friction of the conveyor belt to be transported to the discharge end for discharge.

What are the Advantages of Bucket Conveyor Elevator in Fertilizer Production?

1. Large conveying capacity. This series of

bucket elevator is a similar structural size conveying capacity elevator among

similar domestic elevators, and the lifting capacity is 50m3/h ~500m3/h.

2. Wide range of improvement. This type of

bucket elevator has less requirements for the types and characteristics of

materials. Not only can the general powdery and small granular fertilizer be

upgraded, but also the more abrasive materials can be upgraded. The temperature

is required to be ≤200℃.

3. The driving power is small. Adopt

inflow-type feeding, induction-type discharging and large-capacity hoppers

intensively arranged. There is almost no material return and digging phenomenon

when the material is hoisted, so there is less ineffective power, which can

save 30% of power than the chain hoist.

4. High lifting height. The plate chain

type high-strength chain is adopted, and the lifting height can reach 60 meters

under the rated conveying capacity.

5. Convenient operation and maintenance,

with few wearing parts.

6. The bucket type of conveyor has good structural

rigidity and high precision. The casing is folded and embossed in the middle,

and after welding, it has good rigidity and beautiful appearance.

In addition, our factory can provide other conveyor machines. You can visit the following website to read more. https://www.fertilizerfactorymachine.com/conveyor-belt-machine-for-sale/

Email: info@fertilizerfactorymachine.com

Mobile Phone: +86 180 3757 2883

Comments

Post a Comment